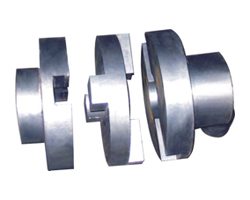

1-半联轴器

2-滑块

3-套筒

4-压注油杯

5-弹性挡圈

公称转柜 | 许用转速 | d1 | D0 | D | L | h | d2 | c | 质量 |

120 | 15 | 32 | 70 | 95 | 10 | 18 | 0.5+0.30 | 1.5 | |

17 | 20 | 1.47 | |||||||

18 | 22 | 1.43 | |||||||

250 | 20 | 45 | 90 | 115 | 12 | 25 | 2.68 | ||

25 | 30 | 2.55 | |||||||

30 | 34 | 2.60 | |||||||

500 | 36 | 60 | 110 | 160 | 16 | 40 | 5.57 | ||

40 | 45 | 5.21 | |||||||

800 | 45 | 80 | 130 | 200 | 20 | 50 | 10.00 | ||

50 | 55 | 9.46 | |||||||

1250 | 55 | 95 | 150 | 240 | 25 | 60 | 15.40 | ||

60 | 65 | 14.46 | |||||||

2000 | 65 | 105 | 170 | 275 | 30 | 70 | 22.41 | ||

70 | 75 | 21.29 | |||||||

3200 | 75 | 115 | 190 | 310 | 34 | 80 | 31.50 | ||

80 | 85 | 29.80 | |||||||

5000 | 95 | 130 | 210 | 355 | 38 | 90 | 10+0.30 | 44.77 | |

90 | 95 | 42.46 | |||||||

8000 | 95 | 140 | 240 | 395 | 42 | 100 | 59.44 | ||

100 | 105 | 57.02 | |||||||

10000 | 110 | 170 | 280 | 435 | 45 | 115 | 91.50 | ||

120 | 130 | 84.29 | |||||||

16000 | 130 | 190 | 320 | 485 | 50 | 140 | 129.55 | ||

140 | 150 | 120.0 | |||||||

20000 | 150 | 210 | 340 | 550 | 55 | 160 | 162.55 |

注:半联轴器和十字滑块材料:45钢,ZG310-570,表面淬火46~60HRC:套筒材料:Q235A钢。

凸榫与凹榫工作面压强验算:

P=6TcD/(D3-d31)h ≤ 【p】

式中

T8——计算转矩,N·m;

D——十字滑块的外径,mm;

d1——十字滑块的内径,mm;

h——十字滑块凸榫的高度,mm;

【p】许用压强,当半联轴器和十字滑块均为淬火钢,润滑良好,【p】=15~30MPa。当半联轴器为淬火钢,十字滑块为铸铁;

【p】=10~15MPa。